Collection: Asphalt Cleaners

What is Asphalt Cleaners?

Different surfaces and equipment called asphalt cleaners allow specialized chemical solutions to dissolve, break down, and remove bituminous materials, tar, and hardened asphalt. These powerful formulations prevent permanent damage to valuable assets by effectively loosening harsh petroleum-based residue. The building sector mostly depends on asphalt removers to keep tools, including pavers, rollers, and trucks. In road maintenance, manufacturing facilities, municipal operations, and commercial cleaning services where asphalt pollution presents operational difficulties, these products also play vital roles. These technologies especially help fleet managers and equipment operators to prevent expensive equipment damage and increase the lifetime of machines.

Types of chemicals for removing asphalt

The asphalt cleaning industry offers several distinct product categories. Each is developed to tackle particular difficulties with asphalt removal and upkeep. Knowing the variations among these items helps experts choose the correct one for their individual needs.

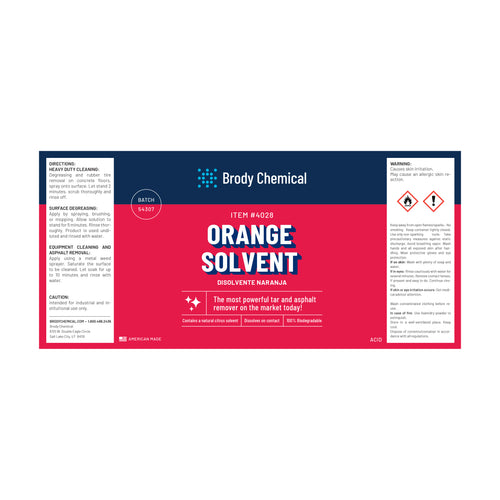

Asphalt and Tar Removers

Asphalt and tar removers are the most aggressive cleaning solutions, especially for dissolved and breaking down tough asphalt deposits. These products comprise strong solvents that flow through thick layers of solidified asphalt. Hence, they are ideal for treating large buildup on machines and surfaces.

Key characteristics:

- High solvent concentration for maximum dissolving power

- Typically, petroleum-based or citrus-derived active ingredients

- Fast-acting formulas that work within minutes on thick deposits

- Often require minimal mechanical agitation to be effective

Applications:

- Removing hardened asphalt from construction equipment

- Cleaning asphalt residue from concrete surfaces

- Restoring metal surfaces affected by asphalt overspray

- Reclaiming tools contaminated with dried asphalt

Because of their powerful solvent qualities, most asphalt removers in this category need correct ventilation during operation. When using these strong cleaning products, users should exercise safety measures, including suitable personal protective gear.

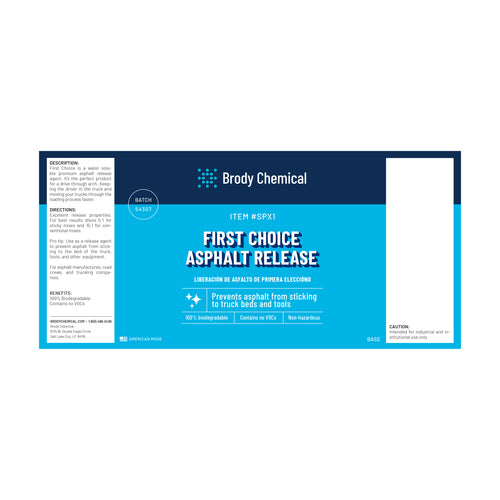

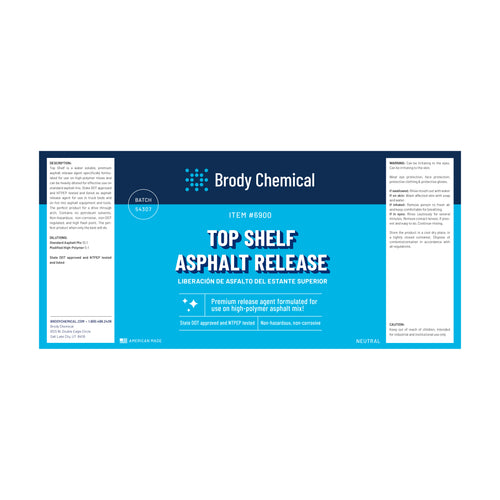

Asphalt Release Agents

An asphalt release agent serves a preventative rather than reactive function. These products create a chemical barrier between asphalt materials and the surface they might otherwise adhere to.

Key characteristics:

- Non-stick properties that prevent initial bonding

- Often, water-based formulations for easier application

- Lower VOC content than traditional removers

- Can be sprayed or applied before asphalt contact

Applications:

- Treating truck beds before loading hot asphalt

- Coating paver equipment surfaces before operations

- Protecting concrete forms and tools

- Preventing accumulation on rollers and finishing equipment

Beyond more traditional diesel-based methods, modern asphalt release agents provide environmentally friendly substitutes that retain performance while lowering occupational dangers and environmental effects. By stopping adhesion before it starts, these chemicals greatly shorten cleanup times and extend equipment life.

Asphalt Cleaning Solvents

Asphalt cleaning solvents occupy a middle ground between preventative agents and aggressive removers. These specialized formulations dissolve fresh asphalt residue while being gentle enough for regular maintenance cleaning.

Key characteristics:

- Balanced solvent strength for everyday cleaning

- Often available in ready-to-use formulations

- May incorporate surfactants for improved cleaning performance

- Less aggressive odor than heavy-duty removers

Applications:

- Daily equipment maintenance and cleaning

- Removing fresh asphalt spills before hardening

- General cleanup of work areas and surfaces

- Cleaning tools and small equipment parts

These solvents work best when used consistently as part of a maintenance program rather than for remedial cleaning of heavily contaminated surfaces. Regular use of appropriate asphalt cleaning products in this category prevents buildup that would otherwise require more aggressive treatment.

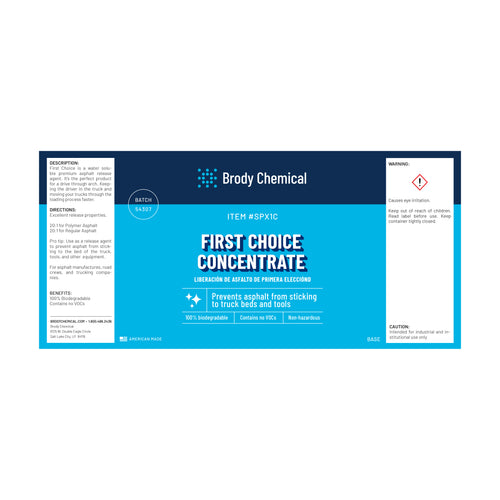

Concentrated Asphalt Cleaners

Concentrated formulas provide economic and logistical advantages for operations requiring large volumes of cleaning solutions. These products ship as concentrated solutions that users dilute on-site.

Key characteristics:

- High concentration of active ingredients

- Customizable dilution ratios for different applications

- Reduced shipping and storage costs

- Often incorporate multiple cleaning mechanisms

Applications:

- Large-scale equipment cleaning operations

- Municipal maintenance departments

- Asphalt production facilities

- Commercial cleaning contractors

Changing the dilution ratio allows users to produce either more aggressive solutions for difficult circumstances or maintenance-level cleansers. For activities involving varied degrees of contamination across different equipment or surfaces, this adaptability makes concentrated asphalt cleaners especially useful.

Asphalt Cleaner Sprays

Ready-to-use spray formulations provide convenience for spot treatment and smaller applications. These products combine effective cleaning formulas with application systems designed for precise delivery.

Key characteristics:

- Pre-mixed solutions ready for immediate use

- Spray applicators for targeted delivery

- Often include foaming action for vertical surface adhesion

- Convenient packaging for field use

Applications:

- Spot cleaning small areas of contamination

- Field maintenance of portable equipment

- Quick response to fresh spills

- Detail cleaning of equipment components

The convenience of asphalt cleaner spray products makes them ideal for maintenance crews who need effective solutions without the complexity of mixing or specialized application equipment.

Choosing the Right Product

Selecting the appropriate asphalt cleaning products depends on several factors:

- The age and thickness of the asphalt deposit

- The surface material being cleaned

- Environmental considerations, including runoff and VOC regulations

- Available application equipment and methods

- Frequency of cleaning needs

FAQs

Got a question? We are here to answer